Contents

Introduction

Understanding the CNC Aluminum Profile Machine

Core Components and Working Principles of a CNC Aluminum Profile Machine

Types of CNC Aluminum Profile Machines and Their Applications

Precision Capabilities and Multi-Axis Configurations

Workflow, Automation, and Software Integration

Key Advantages of Using a CNC Aluminum Profile Machine

Choosing the Right CNC Aluminum Profile Machine for Industrial Needs

Conclusion

FAQ

Introduction

A modern manufacturing environment depends on equipment that can deliver consistent precision, flexible processing, and high productivity. Aluminum profiles—widely used in automation, construction, transportation, aerospace, and industrial machinery—require machining solutions that can keep up with advanced production requirements. A cnc aluminum profile machine fulfills this need by combining automated motion control with specialized cutting, milling, drilling, and routing capabilities. This article explores the complete picture of what a CNC aluminum profile machine is, how it works, why it matters, and how different machine formats serve various industrial applications.

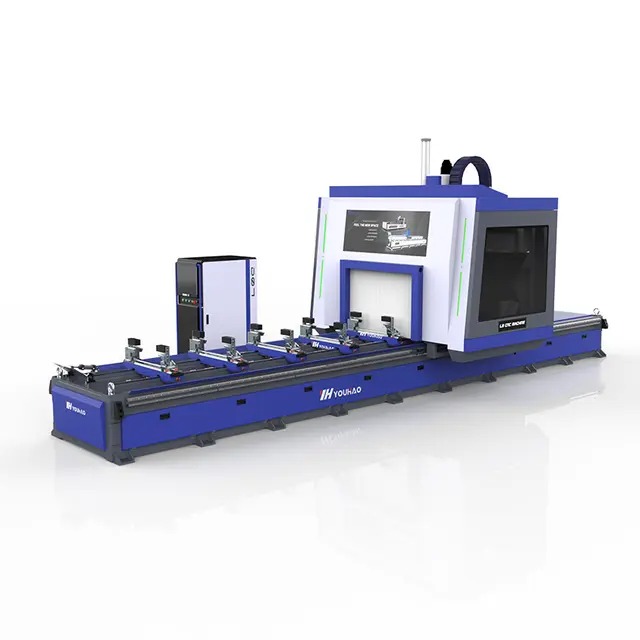

Understanding the CNC Aluminum Profile Machine

A cnc aluminum profile machine is an advanced, computer-controlled processing system designed specifically for machining aluminum profiles into precise shapes, cut lengths, and functional components. Unlike standard milling or routing machines, it integrates long-stroke structures—often 3000Mm, 6000Mm, 4500Mm, or 7000Mm—to handle full-length profiles used in doors, windows, curtain walls, automation systems, vehicle frames, and extrusion-based components.

These machines automate critical processes such as milling, contouring, drilling, tapping, slotting, chamfering, and end cutting. Because aluminum profiles vary in geometry—square tubes, custom extrusions, T-slot profiles, or structural frames—a CNC system ensures repeatable accuracy regardless of size or complexity. Advanced versions such as 5axis 7000mm cnc aluminum profile machine center or 3 Axis High Precision Industrial Drilling Milling Cutting Center further enhance flexibility by supporting multi-directional machining in a single setup.

In essence, the machine solves three core challenges:

Achieving consistent tolerances over long extrusions

Reducing manual labor and alignment errors

Increasing throughput while supporting customizable shapes

![cnc aluminum profile machine cnc aluminum profile machine]()

Core Components and Working Principles of a CNC Aluminum Profile Machine

A cnc aluminum profile machine operates as a coordinated system, integrating mechanical components, automation software, and servo-driven motion technologies. Its structure generally includes a long bed frame, clamping fixtures, cutting spindles, servo motors, and industrial controllers.

A typical high-performance configuration such as a 3000MM 3 Axis CNC Drilling and Milling Machine for Aluminum Profile includes essential components:

Long-axis bed platform that holds profiles ranging from 3m to 7m

High-speed spindle capable of aluminum-specific cutting speeds

Servo-driven linear guides for precision positioning

Automatic tool changers for multi-step procedures

CNC controller for program execution and custom machining logic

How the machine works

Profile Loading – Operators position aluminum profiles manually or via automated feeding systems.

Clamping & Alignment – Pneumatic or hydraulic clamps secure the profile to avoid vibration during machining.

CNC Program Execution – The system interprets CAD/CAM instructions and moves the spindle along predefined toolpaths.

Cutting Operations – Milling, drilling, end-face processing, slotting, and tapping are completed sequentially or simultaneously.

Quality Verification – Onboard measurement systems ensure dimensional accuracy.

Advanced platforms, including Automatic Aluminum Profile Processing Center systems, further incorporate robotic handling, automatic repositioning, and real-time monitoring to minimize operator involvement and maximize consistency.

Types of CNC Aluminum Profile Machines and Their Applications

Different industrial sectors require different machining configurations. Although all machines fall under the umbrella of cnc aluminum profile machine technology, each format is designed for a distinct purpose.

1. 3-Axis Linear CNC Profile Machines

Machines like 3 Axis High Precision Industrial Drilling Milling Cutting Center specialize in precise yet straightforward operations—cutting, contouring, drilling, and surface milling. These are ideal for:

2. Travel-Length-Based Machines: 3000Mm to 7000Mm

Options such as 3000Mm, 4500Mm, 6000Mm, and 7000Mm cnc aluminum profile machine categories support varying production needs:

3000Mm: compact production, small components

4500Mm: medium-length frames, vehicle parts

6000Mm–7000Mm: large-scale building profiles, aerospace assemblies

3. 5-Axis CNC Aluminum Profile Centers

A 5axis 7000mm cnc aluminum profile machine center allows machining from the top, sides, front, and at compound angles. This eliminates re-clamping and significantly boosts precision. Applications include:

Aerospace structural frames

EV battery tray profiles

Automation equipment parts

Extruded industrial machinery components

4. Automated Processing Centers

Systems such as the Automatic Aluminum Profile Processing Center integrate loading, cutting, drilling, slotting, labeling, and unloading. They are widely used in mass-production environments where unattended machining is essential.

Precision Capabilities and Multi-Axis Configurations

Precision determines not only structural viability but also the functional performance of aluminum assemblies. A cnc aluminum profile machine provides the accuracy required for high-end manufacturing.

Multi-axis performance

3-axis systems handle vertical and horizontal machining with reliable accuracy.

4-axis systems add rotational capability to access profile sides.

5-axis systems introduce full angular machining, solving complex geometric challenges.

What precision means in real applications

T-slot extrusions must maintain exact dimensions for bolt alignment.

Aerospace or EV structural profiles require extremely tight tolerances.

Curtain wall frames need perfectly machined surfaces for weather resistance.

Example Comparison Table: Axis Differences

| Feature | 3-Axis Machine | 5-Axis Machine |

| Machining Directions | X/Y/Z | X/Y/Z + rotations |

| Repositioning Needed | Often Required | Rarely Required |

| Ideal Use | Standard profiles | Complex geometry |

| Typical Machine Example | 3000MM 3 Axis CNC Drilling and Milling Machine for Aluminum Profile | 5axis 7000mm cnc aluminum profile machine center |

These precision levels enable manufacturers to adapt aluminum profiles to virtually any structural or mechanical design.

Workflow, Automation, and Software Integration

A modern cnc aluminum profile machine relies on integrated digital workflows to optimize production. Automation enhances accuracy while reducing human involvement.

Key elements of an automated workflow

CAD/CAM Integration – Allows importing DXF, STEP, or IGES drawings for direct machining.

Auto Tool Changing – Smooth transition between milling, drilling, slotting, and tapping.

Intelligent Clamping Systems – Automatically reposition clamps away from tool paths.

Sensor-Based Monitoring – Detects spindle load, tool wear, and vibration.

Data Tracking – Provides reporting for production management.

Example Table: Automation Features

| Automation Feature | Benefit |

| Auto repositioning | Full-length machining without manual re-clamping |

| Multi-tool changer | Decreases cycle time for complex parts |

| Software simulation | Avoids collisions and programming errors |

| Profile identification | Reduces batch-processing mistakes |

Advanced systems such as an Automatic Aluminum Profile Processing Center provide nearly hands-free operation, making them suitable for high-volume manufacturing.

Key Advantages of Using a CNC Aluminum Profile Machine

Investing in a cnc aluminum profile machine creates measurable value in performance, cost efficiency, and production capacity.

Key benefits

High dimensional accuracy across long aluminum extrusions

Massively reduced labor costs through automation

Consistent repeatability, crucial for batch production

Higher machining speed due to optimized spindle performance

Support for both simple and complex profiles

Customizable configuration, including 3000Mm–7000Mm travel lengths

Excellent surface finish, reducing post-processing

Because aluminum is softer than steel, specialized spindles and tool paths significantly improve machining speeds compared to traditional CNC equipment. This makes the cnc aluminum profile machine a cornerstone for companies requiring efficient extrusion fabrication.

![cnc aluminum profile machine cnc aluminum profile machine]()

Choosing the Right CNC Aluminum Profile Machine for Industrial Needs

Selecting the right machine depends on length requirements, production volume, geometric complexity, and automation goals.

Key factors to evaluate

Processing Length

Axis Requirements

3-axis for standard cuts and drilling

4-axis for profile-side machining

5-axis for advanced aerospace or automotive requirements

Material Throughput

Precision Requirements

Budget and Maintenance

This decision-making process ensures that the chosen machine directly aligns with production goals, project complexity, and long-term scalability.

Conclusion

A cnc aluminum profile machine is an essential solution for industries that rely on precise, high-speed aluminum profile machining. By integrating advanced CNC technology, multi-axis control, and automated workflows, these machines reduce labor, increase accuracy, and support diverse industrial applications—from architectural systems to automotive frames and aerospace structures. With configurations ranging from 3000Mm to 7000Mm, 3-axis to 5-axis, and basic models to fully automated processing centers, manufacturers can choose a setup that perfectly aligns with their operational needs. Understanding how these machines work and the problems they solve is the key to making smart investment decisions and unlocking superior manufacturing efficiency.

FAQ

1. What is the main purpose of a CNC aluminum profile machine?

Its primary purpose is to automate milling, drilling, cutting, tapping, and contouring of long aluminum profiles with high accuracy.

2. Can it handle full-length aluminum extrusions up to 7 meters?

Yes. Machines like the 5axis 7000mm cnc aluminum profile machine center are specifically designed for long structural profiles.

3. What industries use these machines?

Aerospace, automotive, construction, automation equipment, renewable energy, and industrial machinery sectors rely on cnc aluminum profile machining.

4. How is it different from a standard CNC milling machine?

A cnc aluminum profile machine is optimized for long extrusions, features longer travel lengths, and provides specialized clamping and machining capabilities.

5. Is automation necessary?

Automation is not mandatory, but systems like an Automatic Aluminum Profile Processing Center greatly improve efficiency and reduce labor costs.