The sign-making industry demands precision, creativity, and fast turnaround. From engraved lettering on acrylic panels to large advertising boards, customers expect results that look professional and last. Meeting these expectations requires more than just skill; it requires equipment designed for efficiency and reliability. At Shandong Youhao Energy Technology Co., Ltd., we provide advanced solutions through our ATC CNC router machines, which are engineered to transform how signs are produced. For sign shops and engraving businesses looking to upgrade, these machines represent a powerful step toward higher productivity and better results.

What Makes an ATC CNC Router Different?

An ATC CNC router machine is defined by its automatic tool changer system. Unlike standard routers that require manual bit swaps, an ATC CNC router can automatically select and change the necessary tool during the cutting or engraving process. This automation keeps the workflow uninterrupted, which is especially important in sign making where multiple operations—engraving, v-carving, drilling, and cutting—are required in a single project.

The construction of ATC CNC routers combines high-speed spindles, precise control systems, and robust tables that firmly hold materials. For example, the 1325 ATC CNC router machine features a working area of approximately 1300 by 2500 mm, perfectly suited for full-sized panels common in the signage industry. The machine is designed to maintain consistent precision even during long runs, enabling businesses to produce signs that meet strict quality standards.

Another advantage is automation beyond tool changes. Modern ATC routers can manage tool offsets, feed rates, and cutting depths automatically, which reduces human error. This is particularly valuable for shops that need to reproduce complex designs consistently across multiple boards.

Why Is It Ideal for Sign Making and Engraving?

Managing multiple tools in a single project is one of the biggest challenges in sign production. A job that starts with fine engraving may later require a larger cutting bit to shape the panel, followed by a different tool for drilling or finishing edges. Without an ATC system, each transition requires manual intervention, which not only consumes time but also increases the risk of misalignment. With an ATC CNC router machine, all tool changes occur automatically and precisely, saving hours of labor over the course of a week.

In addition to speed, the precision offered by ATC routers is a major benefit. Logos, letters, and graphics must remain identical across batches to satisfy customers, especially in branding and commercial signage. Automatic tool changes and accurate spindle positioning ensure repeatable results, while high-resolution control allows intricate engraving details without compromise.

Material versatility is another advantage. Sign shops often work with acrylic, PVC, MDF, aluminum composite panels, and even thin wood sheets. The 1325 ATC CNC router machine can handle all these materials efficiently, supporting diverse project types and opening the door to new business opportunities. The ability to switch between materials quickly without changing machines significantly increases workshop flexibility.

Beyond these technical benefits, ATC CNC routers contribute to workflow optimization. Operators can load materials, start the program, and let the machine complete multiple steps without constant supervision. This efficiency frees up staff to focus on design, finishing, or customer interactions, improving overall productivity and satisfaction.

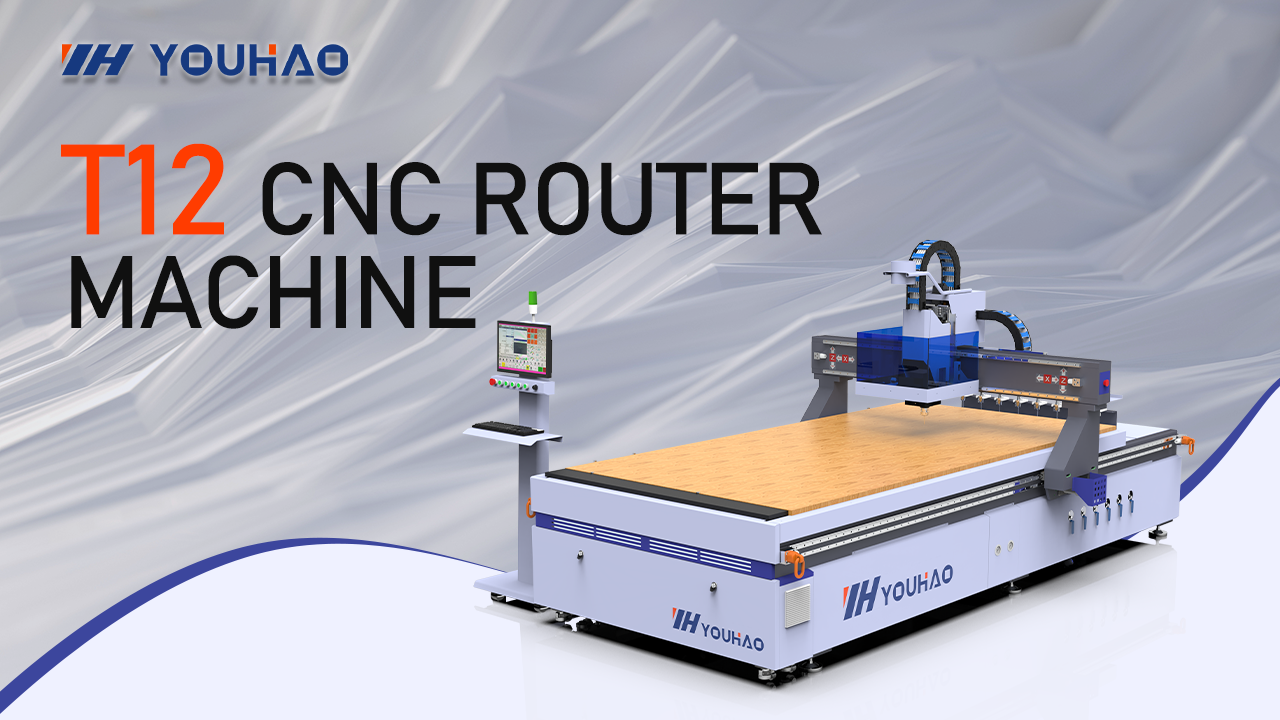

![T12 T12]()

Key Features to Evaluate for Sign Shops

When choosing an ATC CNC router, there are several features that directly impact production quality and efficiency.

Table size is often the first consideration. A 1325 table accommodates standard commercial sheet sizes, which is crucial for both large and medium-scale signage projects. It allows multiple smaller signs to be processed simultaneously or one large panel to be completed in a single setup, minimizing handling time.

Spindle power and speed are also critical. Fine engraving requires high RPM with small bits, while thicker panels or aluminum composites demand more spindle power. Selecting the appropriate spindle ensures clean cuts, sharp edges, and reduced wear on tools.

Tool magazine design determines how many tools can be installed and how quickly they can be swapped. Linear magazines are cost-effective and reliable for moderate workloads, while carousel magazines support high-volume production with rapid changes.

Tool holders and control systems also influence performance. Standard BT30 or ER collets provide stability at high speeds, while a compatible control system ensures designs from CAM software are executed accurately. Modern ATC CNC routers often integrate with advanced software to manage nesting, tool offsets, and cutting sequences automatically, simplifying complex tasks.

Dust control and peripheral options such as vacuum tables, dust shoes, and automatic lubrication further enhance productivity. Maintaining a clean workspace not only protects operators but also ensures the surface finish of signs is flawless.

How an ATC CNC Router Adds Value to Your Business

Investing in an ATC CNC router machine directly translates into tangible benefits for a sign shop. Time savings alone can be substantial. A project requiring three tool changes manually might take 20–30% longer than the same project executed by an ATC machine. Over weeks, this efficiency allows more jobs to be completed without hiring additional staff.

Reliability and low maintenance are additional factors that drive value. With proper care—cleaning tool holders, checking the magazine, and performing scheduled maintenance—an ATC CNC router will run consistently for years. This durability reduces unexpected downtime and ensures that deadlines are met without compromising quality.

Versatility also contributes to business growth. A single machine capable of engraving, cutting, and finishing multiple materials allows sign shops to accept more complex orders, increase pricing for specialized work, and expand their service offerings. Operators can take on high-detail logos, multi-layered signs, or mixed-material projects, positioning the business for long-term success.

Finally, precise and automated operation minimizes material waste. Correct tool selection, controlled feed rates, and accurate depth settings reduce scrap boards and damaged parts, improving cost efficiency.

Practical Considerations Before Purchasing

To maximize the benefits of an ATC CNC router machine, shops should consider several practical aspects. Table size, spindle power, and tool magazine capacity should align with typical project requirements. Support for standard control software ensures that digital designs translate accurately to physical output. Additional features such as automatic lubrication, upgraded dust collection, or servo motors may enhance long-term productivity.

Vendors’ after-sales support and availability of spare parts are also crucial. Machines are only as effective as the service behind them. Ensuring that replacement collets, belts, and pneumatic components are readily accessible reduces downtime and keeps production running smoothly.

Conclusion

An ATC CNC router machine is a transformative tool for sign making and engraving, combining speed, precision, versatility, and reliability. At Shandong Youhao Energy Technology Co., Ltd., we offer high-performance machines designed to meet the demands of modern signage and woodworking businesses. By automating tool changes, handling multiple materials, and ensuring consistent results, our ATC CNC routers help workshops increase productivity, reduce waste, and deliver professional-quality signs. To explore how our machines can elevate your business, contact us today for detailed specifications and personalized consultation.