Contents

Introduction

Understanding the Working Principle of a CNC Oscillating Knife Cutting Machine

Preparing Materials and Workspace Before Cutting

Setting Up the 1625 Cnc Oscillating Knife Cutting Machine

Configuring Cutting Parameters for Different Textiles and Soft Materials

Operating Steps: How To Use a CNC Oscillating Knife Cutting Machine Safely and Efficiently

Advanced Techniques for Precision, Speed, and Edge Quality

Maintenance, Calibration, and Troubleshooting

Conclusion

FAQ

Introduction

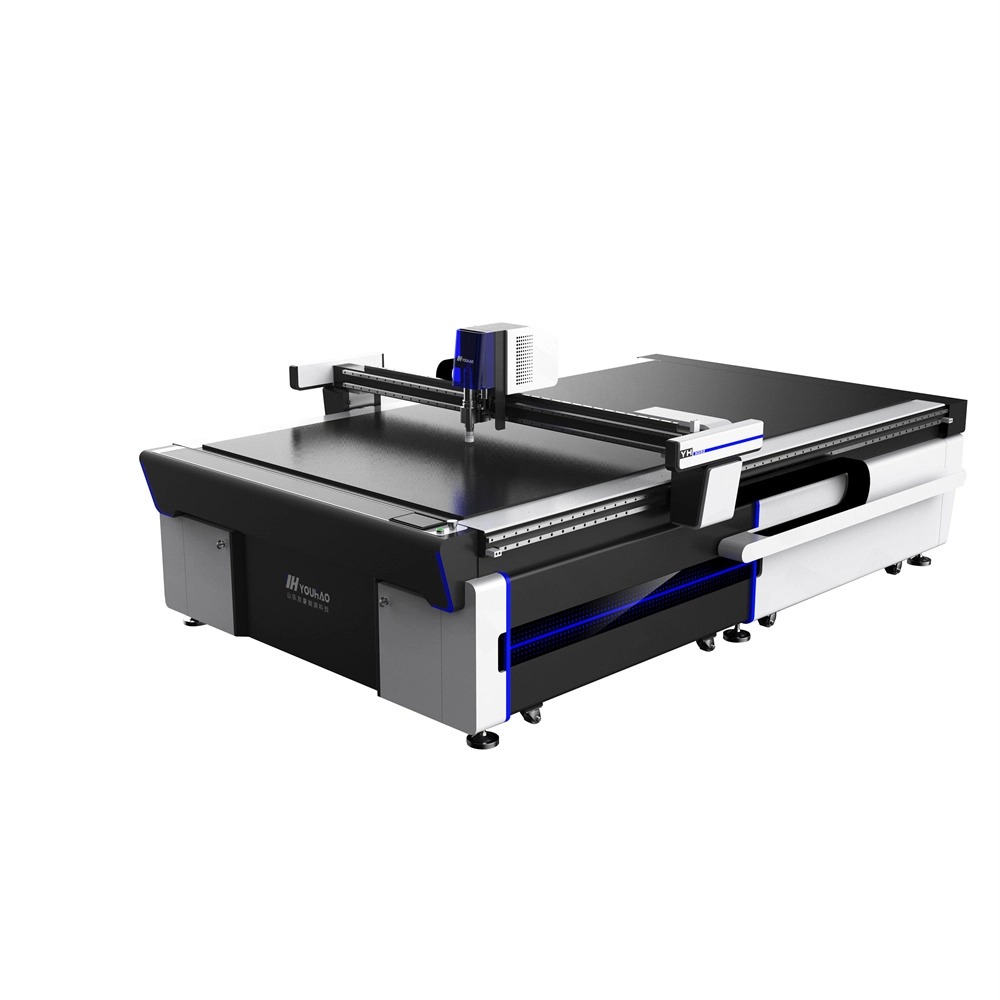

A CNC oscillating knife cutting machine offers manufacturers a fast, precise, and automation-friendly way to process soft materials such as textiles, leather, foams, carpets, composites, and packaging substrates. Mastering its operation is essential for maximizing productivity, extending machine life, and achieving consistent cutting quality across different applications. This guide provides an in-depth walkthrough of How To Use CNC Oscillating Knife Cutting Machine technology, with special focus on the widely adopted 1625 Cnc Oscillating Knife Cutting Machine, its setup, workflow, and performance optimization. From preparing materials to calibrating the knife head and selecting cutting parameters, each section gives practical steps that support real-world use.

Understanding the Working Principle of a CNC Oscillating Knife Cutting Machine

A CNC oscillating knife cutter operates with a high-frequency blade vibration that slices materials rather than burning, melting, or grinding them. The machine relies on a digital toolpath generated from CAD data, allowing highly accurate contouring and nesting. Compared with laser or rotary systems, oscillating knives avoid thermal deformation and produce cleaner edges, especially on thick or fibrous textiles.

The 1625 Cnc Oscillating Knife Cutting Machine is engineered for medium to heavy-duty production tasks, often paired with multi-functional heads capable of bevel cutting, kiss-cutting, creasing, or pen marking. When integrated with industrial servo drives, the cutting head can shift direction rapidly while sustaining consistent knife oscillation frequency. This principle makes it particularly effective for manufacturers using Cnc Textile Cutting Machine 1625 systems for apparel, automotive interiors, furniture foam, industrial fabrics, and packaging samples. Understanding this mechanism ensures operators choose suitable blades, set correct oscillation frequencies, and avoid unnecessary tool wear.

![1625 Cnc Oscillating Knife Cutting Machine 1625 Cnc Oscillating Knife Cutting Machine]()

Preparing Materials and Workspace Before Cutting

Before using any oscillating knife machine, proper preparation prevents feeding errors, inaccurate cuts, and material waste. Begin by ensuring the table is clean, evenly leveled, and free of residual fibers or adhesives. Specialty machines such as the Heavy Duty Cnc Oscillating Knife Cutter often include vacuum suction beds, requiring consistent airflow. Operators should check the vacuum pump, filters, and supply lines to ensure strong material hold-down.

Materials must be spread smoothly without wrinkles. When processing flexible textiles, adding protective layers or backing paper improves stability. For thicker materials—such as those cut on a 1625 Fabric Textile Circular Bevel Knife Industrial Cutting Machine—pre-flattening foam or multi-layer fabric helps maintain depth consistency. For rolls, tension should be carefully controlled during unwinding. Proper preparation not only improves cut accuracy but also reduces strain on the oscillating blade and drive system.

Setting Up the 1625 Cnc Oscillating Knife Cutting Machine

Setting up the machine involves calibration, tool selection, and workflow configuration. The 1625 Cnc Oscillating Knife Cutting Machine typically supports interchangeable knife tools, including straight oscillating knives, circular bevel knives, V-cut knives, and drag knives. Choosing the correct tool head depends on the project: textile mills may use a standard oscillating knife, while carpet and composite cutters often rely on a 1625 High Precision Textile Circular Bevel Knife Heavy Duty Cutter for thicker or denser materials.

Table: Common Knife Tools and Their Uses

| Knife Type | Suitable Materials | Typical Application |

| Oscillating Knife | Textile, leather, foam | Apparel, upholstery |

| Circular Bevel Knife | Thick fabrics, felt, carpet | Industrial textiles |

| Drag Knife | PVC, stickers | Packaging, signage |

| V-Cut Knife | Foam board, cardboard | Display materials |

Calibration includes:

Once calibrated, users import CAD files or nesting layouts, assign toolpaths, and confirm cutting layers. Setting the right workflow ensures minimum waste and maximized throughput.

Configuring Cutting Parameters for Different Textiles and Soft Materials

Optimizing cutting parameters is critical for achieving clean edges, especially with machines like the Cnc Textile Cutting Machine 1625. Parameters include knife frequency, cutting speed, depth, and tool pressure. Below are best-practice guidelines.

Table: Example Parameter Ranges

| Material Type | Knife Frequency | Cutting Speed | Depth Setting |

| Soft Textile | Medium-High | Fast | Shallow |

| Leather | High | Medium | Medium-Deep |

| Thick Felt | Medium | Slow | Deep |

| Foam | Low-Medium | Medium | Deep |

These values vary depending on the blade type and the horsepower of systems like the Heavy Duty Cnc Oscillating Knife Cutter. Incorrect settings may cause frayed edges, incomplete cuts, or blade overheating. Operators should test on sample pieces before starting full production. Adjustments such as adding lubrication, changing the oscillation amplitude, or modifying the knife angle can significantly enhance quality.

Operating Steps: How To Use a CNC Oscillating Knife Cutting Machine Safely and Efficiently

Operating the machine includes loading materials, starting the job, supervising the cutting process, and removing finished parts. Begin by engaging the vacuum suction, confirming hold-down strength, and performing a dry-run without cutting to verify the toolpath.

Once ready, start the job from the control panel. The 1625 Cnc Oscillating Knife Cutting Machine will follow the programmed toolpath, adjusting speeds and frequencies automatically. Operators should remain near the machine to monitor blade movement, material shifting, or unexpected vibrations. Machines equipped with circular bevel heads—like the 1625 Fabric Textile Circular Bevel Knife Industrial Cutting Machine—require extra attention when cutting multi-layer materials because the blade friction can increase heat and resistance.

When the job finishes, release the vacuum and carefully lift materials without distorting edges. Label parts immediately for batch consistency. Proper operation reduces downtime and ensures repeatable accuracy across production cycles.

![1625 Cnc Oscillating Knife Cutting Machine 1625 Cnc Oscillating Knife Cutting Machine]()

Advanced Techniques for Precision, Speed, and Edge Quality

Advanced users can refine productivity by applying multi-layer cutting, smart nesting strategies, or automated conveyor feeding. For high-output textile factories using the 1625 High Precision Textile Circular Bevel Knife Heavy Duty Cutter, advanced nesting can dramatically reduce waste and increase cutting capacity. Software modules can automatically rotate patterns, manage seam allowances, and simulate knife paths to avoid collisions.

To boost precision, operators can fine-tune the oscillation amplitude, switch to sharper blade materials, or implement segment-wise speed adjustments for corners. For very tight curves, reducing speed minimizes edge tearing. Users of the 1625 Cnc Oscillating Knife Cutting Machine also benefit from using specialized anti-static mats, lubrication systems, and automatic tool-change features for improved workflow. These techniques support consistent industrial-grade performance in automotive fabrics, sportswear, aerospace composites, and footwear manufacturing.

Maintenance, Calibration, and Troubleshooting

Routine maintenance preserves cutting quality and machine lifespan. Begin by checking blade sharpness, tool alignment, vacuum bed cleanliness, and the condition of felt cutting mats. Lubricate bearings and inspect belts regularly. Machines like the Heavy Duty Cnc Oscillating Knife Cutter typically endure high workloads and require periodic replacement of consumables such as blades, filters, and vibration pads.

If cuts are inconsistent, operators should recalibrate the Z-axis or verify that the oscillation frequency matches the material profile. Poor vacuum suction often results in material drift, which can be corrected by sealing unused vacuum zones. Unusual noise from the oscillating head can indicate improper blade installation or worn-out moving parts. By maintaining the machine weekly, users ensure stable performance whether operating a Cnc Textile Cutting Machine 1625 or a 1625 Fabric Textile Circular Bevel Knife Industrial Cutting Machine.

Conclusion

Learning How To Use CNC Oscillating Knife Cutting Machine equipment effectively allows operators to achieve precise, clean, and repeatable cuts across a wide range of soft materials. The 1625 Cnc Oscillating Knife Cutting Machine and its heavy-duty variants provide industrial-level capability, but optimal performance depends on proper setup, accurate parameter configuration, and consistent maintenance. By mastering workflow techniques—from material preparation to knife selection—manufacturers can significantly improve cutting efficiency, reduce waste, and maintain consistent quality for textiles, foam, leather, carpet, and composite products.

FAQ

1. What materials can a CNC oscillating knife cutting machine process?

It can cut textiles, leather, carpet, foam, carbon fiber, gaskets, rubber, packaging materials, and composite fabrics. The correct blade type ensures clean edges.

2. Is the 1625 Cnc Oscillating Knife Cutting Machine suitable for mass production?

Yes. Its working area, servo drive system, and high-frequency oscillation make it ideal for medium- to high-volume manufacturing.

3. What is the difference between an oscillating knife and a circular bevel knife?

An oscillating knife vibrates rapidly for precision soft-material cutting, while a circular bevel knife rotates to slice thick or dense textile layers.

4. How often should the blades be replaced?

Frequency varies by material and workload. Heavy-duty cutting—especially on machines like the 1625 High Precision Textile Circular Bevel Knife Heavy Duty Cutter—requires more frequent blade changes.

5. Do I need specialized software?

Yes. CAD/CAM software for nesting and toolpath generation is essential for optimal cutting efficiency and accuracy.